INTRODUCTION

With the rising global energy crises , Alternate source for power generation are being explored, But issues with most of energy production sources are increasing Carbon foot prints. As a result Green energy sources are preferred that generates power with natural resource harvesting i.e water flow or sunlight.

USE OF SOLAR ENERGY FOR ENERGY CRISES SOLUTION

In Countries with long Day Light time, Solar Energy Production is being the top priority for individuals for overcoming their power needs for households and industrial purpose.For Residential Solar Power Projects, People utilise their empty roof top spaces by mounting solar panels either on floor or on Elevated structure if one wants to utilise roof top floor for other purpose.

INTEGRATION OF SOLAR PLANTS IN EXISTING INDUSTRIAL STRUCTURE

Where as for Industrial and Comparatively large scale projects , Only place available in most of factories are the top surface area of warehouse and workshops shed. These shed’s top area’s are mainly built with corrugated metal sheets being at support of metal guarders beneath after distance of 4 to 5 ft , providing enough reinforcement to place solar panels.

NEED FOR ROUTINE CLEANING OF PLATES IN POLLUTED CITY LIKE KARACHI

Problems are not over by just installing solar panels. If we talk about Pakistan and its Economic Hub city’s industrial zones i.e Korangi Industial Area , Port Qasim Industrial Area, Nooriabad Industrial Area , S.I.T.E Area and many other in Karachi City , all these face high wind and dust issues along with chemical fumes and small light weight waste particles that cover surface area of solar panel and decrease their efficiency gradually , creating a demand for weekly maintenance and cleaning in order for industry to meet its power requirements. Same are the problem scenario in other cities of Pakistan i.e Lahore, Faisalabad, Gujranwala, Islamabad and their industrial estates.

NEED FOR SOLAR WALKWAYS

For purpose of solar Panel routine cleaning, panels must be installed in such a way that their is gap for walking path around every 8-10 square meters of panels, these walking path are usually called WALKWAYS or SOLAR WALKWAYS as they are installed at solar power plant.

While designing walkways this must be made sure that its wide enough for a person to move around along with his all equipment for cleaning or resolving electrical or mechanical problems if any. Minimum recommended width for solar walkways is 15″ and maximum is 24 “. Making walking platforms too wide will reduce space for solar panels and increases unwanted load over shed.

Problems with Metal and Aluminium Walkways

In search of material for construction of walkways most people end up at Metal checked plate which needs paint or coating after every 6 to 12 months to avoid from rusting and corrosion. Walkway which are used for maintenance of solar panels needs its own maintenance in this case and also being heavy in weight it adds unwanted load over PEB shed structure.

On other hand projects around coastal areas or near the more corrosive environment , Many Engineers in Pakistan due to lack of awareness opt for aluminium solar walkways , which takes lots of time and joints with nuts and bolts to be fabricated.

Secondly being conductor of Electricity it increase the electric shock threat to person walking over in case of any loose wire from solar panels are in contact.

FIBREGLASS REINFORCED PLASTIC (FRP) AS TOP MATERIAL PRIORITY FOR WALKWAYS

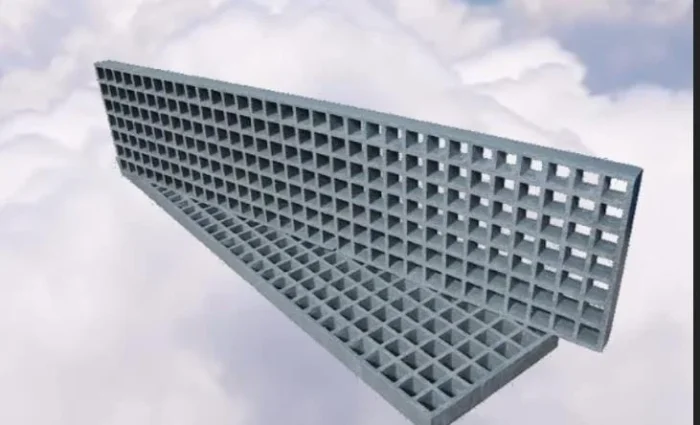

To Resolve all the problems mentioned above only solution is to use FRP Gratings panels as Solar Walkways ,being made from Fiberglass it ensures that its light weight and corrosion free even in most acidic and humid environments. Following are the added advantages mentioned below:

Light Weight

Gratings are moulded in such a way leaving empty pocket mesh that ensures durability & Strength along with space for water and dirt to drain out from these spaces which also make it very light and is never a burden over the shed structure.

Corrosion & UV Resistant

As Fibreglass reinforced plastic are kind of plastic , so being rusty is never an issue, On other hand being kept under sun, it can last for more than five years being exposed to ultra violet light.

Shock Proof

As plastic are insulator to electricity these walkways are the safest spot to be at even if complete structure is in contact to electrical pulse from faulty wiring or any other electrical problem.

Maintenance Free

Best part of these fiberglass walkways is that they are self sufficient for years in terms of cleaning and maintenance, every time you just step over and its ready to serve you for job to clean solar panels.

Fire Retardant

Fire is the second most alarming threat after electric shock , whenever there is a short circuit or even in case of Lightning fall fire can be caught. FRP gratings being fire retardant ensures that fire don’t spread and turn down as soon as fire goes away.

Cost and Conclusion

With all the comparison done above fibreglass gratings should be the top priority for solar walkways for industries who can invest a little more for in beginning and relax for a decade in terms of maintenance along with having maximum power output as these will help clean panels easily.